In the realm of industrial innovation, advancements in technology continuously redefine efficiency and precision across various sectors. Two such areas of significant development are laser cutting methods and efficient barge unloading equipment. Each plays a crucial role in enhancing productivity, reducing costs, and improving safety standards in their respective fields.

Laser Cutting Methods: Precision in Manufacturing

Introduction to Laser Cutting

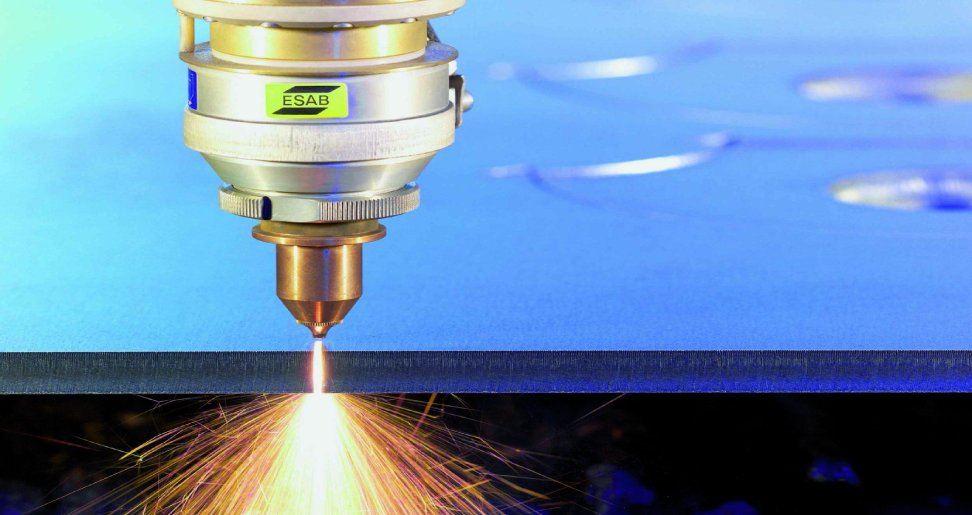

Laser cutting has revolutionized manufacturing processes by offering unparalleled precision and flexibility. Utilizing high-powered lasers focused through optics, this method allows for the precise cutting of materials ranging from metals to plastics with exceptional accuracy and minimal waste.

Applications Across Industries

Industries such as automotive manufacturing, aerospace, electronics, and even artistic endeavors benefit from laser cutting technology. Its ability to intricately cut and engrave materials at high speeds makes it indispensable for producing complex components and detailed designs.

Types of Laser Cutting Techniques

- CO2 Laser Cutting: Ideal for non-metallic materials like wood, acrylic, and textiles due to its ability to produce clean edges and intricate designs.

- Fiber Laser Cutting: Known for its efficiency in cutting metals, particularly steel and aluminum, fiber lasers offer faster processing speeds and lower maintenance requirements compared to traditional methods.

Advantages of Laser Cutting

- Precision: Laser cutting ensures high accuracy, reducing the need for manual finishing.

- Versatility: Capable of handling various materials and thicknesses with ease, adapting to diverse manufacturing needs.

- Efficiency: Faster processing times and minimal material waste contribute to cost-effectiveness.

Innovations and Future Trends

Continuous advancements in laser technology focus on improving power efficiency, integrating automation for seamless operation, and expanding capabilities for larger scale applications. These innovations promise to further enhance productivity and sustainability in manufacturing processes.

Efficient Barge Unloading Equipment: Streamlining Logistics

Challenges in Barge Unloading

Barge transportation remains a cost-effective and eco-friendly mode of bulk goods transport. However, efficient unloading poses challenges due to varying dock facilities, cargo types, and environmental factors.

Role of Modern Unloading Equipment

To address these challenges, specialized barge unloading equipment has been developed. These systems are designed to handle bulk materials such as grains, aggregates, and chemicals swiftly and safely.

Key Equipment Types

- Conveyor Systems: Utilizing belts or chains, conveyor systems efficiently transfer bulk materials from barges to storage or transport facilities. They can be customized to handle different cargo volumes and types.

- Grabs and Clamshell Buckets: Mechanized grabs and clamshell buckets are used for handling loose bulk materials. They offer flexibility in maneuvering within confined spaces of barges and ensure controlled material discharge.

Advantages of Efficient Barge Unloading Equipment

- Speed and Efficiency: Reduces turnaround times significantly compared to manual handling, optimizing supply chain operations.

- Safety: Minimizes risks associated with manual labor and improves workplace safety standards.

- Environmental Impact: Enhances sustainability by reducing spillage and optimizing energy consumption during the unloading process.

Technological Advancements

Modern barge unloading equipment integrates sensors for precise cargo handling, automation for operational efficiency, and robust designs capable of withstanding harsh marine environments. These advancements aim to further streamline logistics and reduce operational costs for shipping companies.

Conclusion

In conclusion, laser cutting methods and efficient barge unloading equipment exemplify how technology continues to reshape industrial practices. From the intricate precision of laser cutting in manufacturing to the streamlined efficiency of barge unloading systems in logistics, both innovations underscore the drive towards enhanced productivity, sustainability, and safety across diverse sectors.

As industries evolve and technological boundaries are pushed further, the synergy between laser cutting methods and efficient barge unloading equipment exemplifies the transformative power of innovation in shaping the future of industrial operations.

Have A Look :-

- Seint Makeup Review 2023: Before And After

- What Is Now.gg? Can You Play Roblox Games On It?

- 5 Things You Have To Know About Kanye West New Wife

where to buy zithromax without a prescription – purchase tetracycline pill order metronidazole for sale

Your comment is awaiting moderation.